Home " Plastic profiles for mobile homes

Exactly according to your requirements

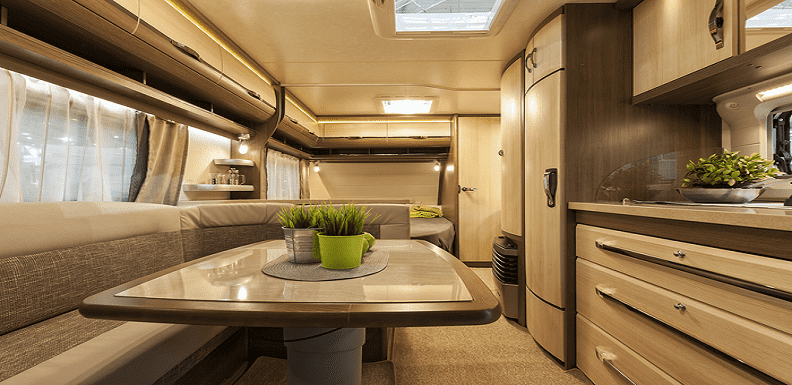

Plastic profiles for mobile homes must primarily perform two tasks: First of all, functionality is a decisive factor. Plastic profiles for mobile homes must withstand extreme forces and be correspondingly durable - with stability at the same time. Weight also plays a role - the lighter, the better. And ultimately also the appearance. A feel-good atmosphere should reign in the motor home or caravan. A feeling of home on wheels.

This is why ttp Papenburg is convincing

Development and manufacturing from a single source

Lightweight construction using state-of-the-art plastics

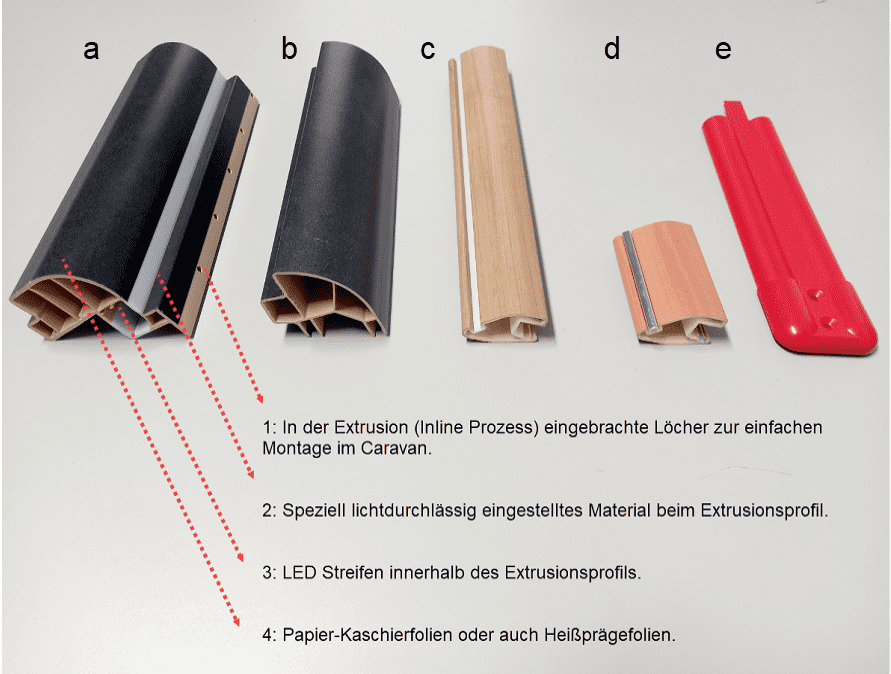

Inline professional machining punching, sawing, milling

Mobile home profiles laminated with the industry's famous paper decorative films

Quality Made in Germany. All profiles for your caravan are 100% produced by us in Northern Germany. We also attach great importance to short delivery routes and secure supply chains of our suppliers when procuring our raw materials. Thus, as a manufacturer in the caravan industry, we ensure a continuous supply under consistently high quality standards for you as a customer.

Stability combined with lightweight construction is our common goal. Some of the profiles have to withstand extreme conditions. Here, over time, especially in outdoor applications, it becomes apparent how durable YOUR plastic profile will be for many years to come.

Appearance and feel play a major role in the caravan. High-quality surfaces, whether brushed, grained, in aluminum look or classic in wood look, are also no problem in the plastic profile area. So-called hot stamping foils or the paper laminating foils commonly used in the caravan industry are always popular options for your plastic profile.

Sustainability has been a recognized goal in the plastics industry for many many years. Thus, the material from the production process is specifically collected and reused. True to the motto old becomes new.

Whether your profiles need to be drilled, punched, milled, specially packaged or otherwise assembled, we are the right partner for you! In our finishing department we can respond flexibly and quickly to your wishes and needs in profile processing at any time.

The subject of UV resistance in plastics is a very important one for Caran applications. Highly UV-resistant plastics are the rule here, especially outdoors. Rain piping, hollow piping, scuff protection strips, etc. must be impeccable even after years of outdoor use of your motor home or caravan.

Here you will find a small selection of the countless plastic profiles that are installed in the motorhomes of our customers:

How to get your custom made plastic profile for mobile homes

Development of a tool for your individual plastic profile

Color requests are implemented in our own laboratory

Production of your individual plastic profiles

Profile finishing in the in-house finishing department

Step 1

Step 2

Step 3

Step 4

Have we aroused your interest?

Then contact us and let our team of proven experts advise you. Together we will find the ideal solution for your individual requirements.

Contact

Daniel Wildermann

Mail: dwildermann@ttp-papenburg.de

Phone: +49 4961 914 157

Business hours

Monday to friday

8:00 till 16:30

If you have any questions, please feel free to contact us at any time.

Technical plastic profiles

FAQ's about plastic profiles for motorhomes

In general, certain minimum quantities apply to extrusion. However, everything can be discussed. If there is an annual consumption quantity of at least 5,000 meters, then partnership purchase quantities can always be agreed together.

Here it goes certainly already with approx. 0,50 €/ mtr. The size of the profiles will certainly be between €1 and €5 per meter.

Almost everything is possible. So-called hot stamping foils, paper decor foils, embossed or brushed plastic profiles are possible.

It is possible to develop plastic caravan profiles specifically so that recycled materials or regrind can be used. This does not detract from the quality, on the contrary. For many applications, a recycled material is the cost-effective solution for your caravan profile project.

We will gladly take up your idea for a plastic profile and develop the ideal solution for your project in the caravan sector together with you. We build "your" extrusion die for your profile solution and supply you reliably for many many years from the extrusion die for the caravan industry.

In most cases a new extrusion die is needed. In this case, you can expect a delivery time of 8-12 weeks (depending on the degree of difficulty) for the initial samples.

Whether you need soft, semi-hard or hard profiles; you are right with us. Starting from the sealing profile to the elaborate profile, which is used as a cabinet frame profile, we are happy to help you here.

Here, too, a wide range is possible, depending on the area of application. Hard PVC, soft PVC, ABS, ASA, PP, HD-PE, LD-PE, PC, PET-G, PMMA, TPE, EVA or even Resysta are all common and possible materials in caravan construction.

In the caravan sector, plastic profiles are designed for a long life cycle. In consultation with you, we discuss the requirements for the plastic profile and thus specifically determine how long the profile must at least be in use.

ttp plastic profiles

From the idea to the development to the finished profile. Since 1958, ttp Papenburg GmbH has been manufacturing individual profiles from a wide variety of plastics at the Papenburg site in northern Germany to customer specifications.

Products

Contact

Schulze-Delitzsch-Strasse 23-25

26871 Papenburg

Feel free to contact us by phone, by mail or via our contact form.